custom installations

Remote draft beer systems require precision - all the right parts, in all the right places, maintained and serviced to perform accurately. To do this, you need to be serious about beer.Custom Draft Beer Installations

DraftPro Systems specializes in all aspects of draft beer system installation. No matter the size of the job, from a small direct draw draft system to long-draw, remote draft systems, DraftPro Systems has the equipment and knowledge to make your system work to perfection. We are a Central Florida-based company proud of our reputation for carrying only industry-leading products and provided top-rated service.

Designing Your System

If you can dream it, we can build it. But before we can begin designing your system, you need to answer a few questions. Such as what type of system will best meet your needs.

Direct Draw

A direct draw beer dispensing is usually characterized by draft dispensing towers are positioned directly above a thermostatically controlled refrigeration unit. The refrigeration unit is usually a kegerator. This system is equipped with beer dispensing hardware and 3/16″ inside diameter beer line that can be used exclusively between the keg coupler and faucet.

Short Draw

A long-draw draft system, in which beer is delivered remotely from kegs located in a walk-in cooler to dispensing towers located in service areas. These systems use air to power and cool the beer between the cooler and the faucets. These systems work well for up to approximate 25 feet.

Long Draw

Long-draw draft beer systems are the most common in commercial bars in which multiple kegs are stored within a walk-in cooler so that the temperature can be maintained at optimum levels, refrigerated throughout the dispensing process. These systems use a food-grade antifreeze material called Glycol, which surrounds the beer in different tubes within a trunkline. These systems can use either CO2 or Nitrogen air systems.

Advantages of a Remote, Long-Draw Draft Beer System

- Increased Profits

Draft beer costs less than packaged beer. - Saves Space

Kegs take up less space than bottles and cans. No need to store empties. - More Brands = More Sales

You can serve more brands than a kegerator or keg box. - Greater Flexibility

You can place a service tower just about anywhere in the location for optimal efficiency. Usually requires about 1 square foot of counter space per tower. - Convenience

No need to bring kegs through the restaurant. - Safer for Employees

Eliminates workers compensation claims or workers injuries and anyone can change the keg. - Increased Sales

You will not lose sales waiting for someone to bring out the keg.

Designing a world-class remote, long-draw draft beer system

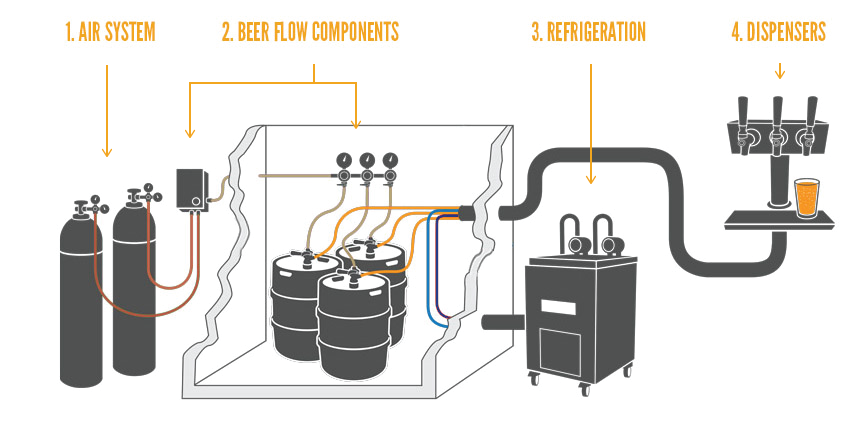

Elements of a remote, long-draw draft beer system

(1) Air and Gas Pressure System

The choice to use CO2 or Nitrogen depends on which type of beer you will be dispensing. If traditional lagers or ales, you will use CO2. For stouts such as Guinness, you will need nitrogen. And if you plan on serving both, then you’ll need both gas pressure types. The two types come in different tanks, with different components, regulators, and fittings.

These components supply pressure to the beer keg from the gas source. Starting with the gas cylinder (a.k.a. air tank). Gas cylinders include a shut-off valve to open and close the gas supply and are manufactured in either aluminum or steel and hold CO2 or CO2 / Nitrogen blend (a.k.a. mixed gas) for systems and products that require a mixed gas pressure source (stouts, etc).

A CO2 regulator regulates the pressure from the gas cylinder (high-pressure source) to the keg coupler (keg tap) connected to the keg valve in the keg (low pressure) where a brewery recommended pressure is prescribed (generally 12-14 lbs in kegerators). A gas regulator contains a manual adjusting screw or knob to regulate the amount of pressure supplied to the keg. A properly adjusted and functioning gas regulator is critically important to maintaining the proper level of CO2 in the beer, too much CO2 gas pressure may add CO2 to the beer and cause foaming problems and too little CO2 gas pressure may cause CO2 to release from the beer causing a flat beer.

(2) Beer Flow Components

The components of a draft beer system include all the equipment from the keg to the faucet. These components include the keg, the keg coupler (keg tap), brewery approved beer, gas line tubing and associated fittings, beer shank assembly and the beer faucet. In a countertop dispensing application, a beer tower is used. The beer tower assembly commonly includes a beer line & fitting, beer shank assembly, and a faucet.

The first component is the keg which contains a valve with a stainless beer flow tube. Most North American Brewers use a 1/2 barrel also known as a full-size keg (15.5 gallons) as the standard keg or a 1/4 barrel (7.5 gallons).

The beer in the keg contains CO2 which is naturally produced during the fermentation process. The level of CO2 in the beer is determined by the brewer and type of beer in the keg (lager, ales, stouts, etc.) The level of CO2 varies by type of beer and because of these differences, the amount of gas pressure applied to the keg will also vary to maintain the proper level of CO2 in the beer during the dispensing process.

The keg coupler, or keg tap, is the beer flow component that opens the valve in the keg and allows gas pressure to enter the keg and for beer to flow out. Not all breweries use the same type of keg valve and beer coupler (keg tap). From the keg coupler, beer will flow through flexible tubing called the beer line to the beer shank assembly and out the beer faucet.

The diameter and length of the beer lines play a major role in controlling the speed of the beer flow at the beer faucet. In Glycol-Cooled draft beer systems where the beers lines can run up to 500 feet the beer line diameter and material specification will vary according to the system requirements.

(3) Refrigeration

There are many configurations for cooling and storing keg beer. These include refrigerators which are also known as kegerators, mobile bar units and walk-in room coolers. All provide the same function by storing the keg under refrigeration at a constant 38˚ F temperature. However, the temperature of the beer is maintained in two main areas of a long-draw, remote systems. First, in the storage of the beer in a walk-in cooler. And then secondly over the entire distance of the beer line from cooler to the faucet. This is achieved by surrounding the beer line with tubes filled with chilled glycol within an insulated trunkline.

DraftPro Systems sells and installs several models of glycol chillers or refrigeration units that can maintain optimal beer temperature up to 500 feet of beer line.

(4) Dispensers

There is a wide assortment of draft beer towers and dispensing faucets. Your choice should depend on business volume and the number of available options on tap. Another consideration is the personality and ambiance of your establishment. Looks can vary from sleek, elegant design to industrial, black iron. We can also design completely custom dispensing or service stations using objects such as surfboards as the backing for beer dispensers.

The most common types include “T” Towers and Pass-Through units.

Draft Beer System Equipment

You can build your own custom system by choosing among the list of some of the more popular options below.